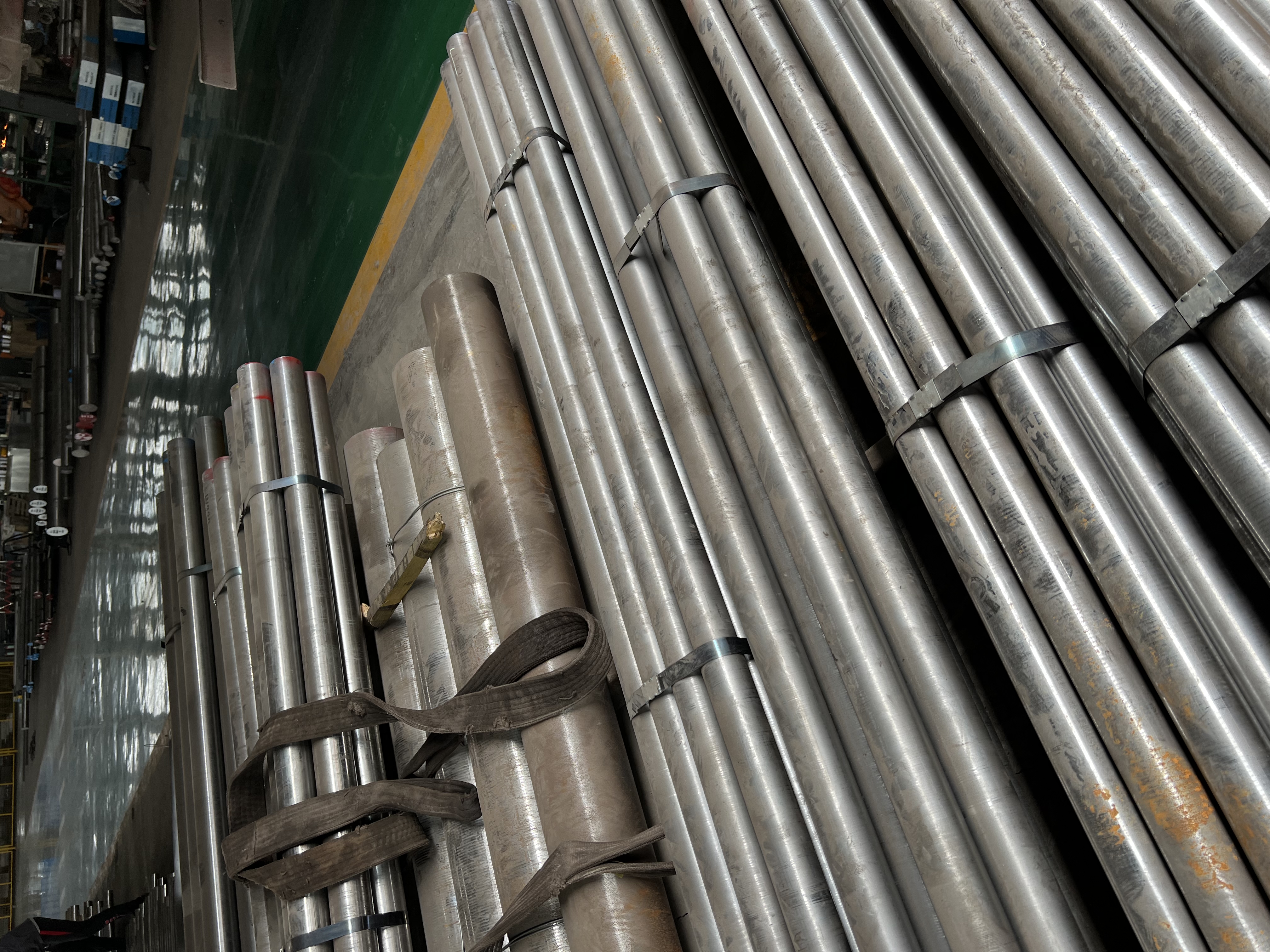

Nastavek za jekleno vrv

- PX

- huangshi

- 10-15 dni

- 10000set/mesec

1). Pri plastičnih kalupih je tudi najpogosteje uporabljeno ločevanje izdelka od kalupa;

2). Nastavek iz karbidne trdine, kot je nastavek iz volframovega jekla, se lahko uporablja za prebijanje daljših in finejših lukenj;

3). Naprstnik se imenuje tudi vrh. Je stožčasta kovinska okrogla palica z glavo, ki je sestavljena na stružnici ali brusilniku, da podpira obdelovanec in povzroči, da se obdelovanec vrti okoli njega, vendar se popolnoma razlikuje od naprstnika dodatkov za plastične kalupe;

4). Plastični nastavek za kalup se lahko uporablja tudi znotraj kalupa, ima lahko stabilizacijsko vlogo in se imenuje vstavljena igla.

Vrste plastičnih kalupov vključujejo: ploščate naprstnike, kupolaste zatiče, zatiče, standardne naprstnike, nestandardne naprstnike itd.

Materiali nastavka iz plastičnega kalupa so SKH51, SKD61, SKD11, 65Mn itd.

SKH51 nastavek ima boljšo žilavost kot SKD61; Nastavek SKD61 lahko prenese visoko temperaturo 1600 ℃, površina nastavka SKD61 pa lahko izboljša odpornost proti obrabi nastavka po nitriranju. Naprstnik 65Mn je slabe kakovosti, krhek in ga je lahko zlomiti. Nekateri plastični kalupi niso več sestavljeni in uporabljeni z nastavkom 65Mn.

Standard model of thimble for lathe and grinder:

The standard for fixed thimble is GB/T9204.1-1988, and the standard for rotary thimble is JB/T3580-1998

Design standards for thimble and matching plastic molds

1. If the thimble is less than 3mm, use two thimble.

2. The top block that is ejected with a rod requires the rod to be inserted into the top block 8 mm. The top block must have a guide sleeve, and the guide sleeve must be fixed

3. If the small top block cannot be fixed with screws, please design with pins for positioning

4. The R angle of the top piece must be designed

5. In the case that the mold can use either the top sheet or the ejector pin, the ejector pin will be given priority.

6. The thimble has 20-25mm left.

7. The left and right gap of the thimble plate penetrates 0.5 mm.

8. The thimble board must have a lower guide post and trash nails.

9. When resetting the thimble plate, try to give priority to the ejector accessories (except for the spring required by the customer)

10. Try to use a larger ejector pin (force and life) for ejection.

11. On the premise that the product can be automatically taken off with the inclined top, try to avoid using the gas top.

12. The core and cavity valves should be designed to be concentric (especially transparent products).

13. The mold design carefully calculates the ejection distance to avoid insufficient ejection stroke.

14. For products that do not have the original shape, carefully consider the ejection position and ejection method.

15. Place the oil cylinder on the ejector plate for the mold ejected from the oil cylinder.

16. The valve installation should be disassembled from bottom to top.

17. Try not to fix the core in the push tube with screws, it must be fixed with a pressure plate.

18. The thimble on the inclined surface, the thimble step design is long and bar-shaped to avoid the inconvenience of D-shaped processing.

19. The board under the fixed screw of the inclined top sliding foot is designed to be worn and easy to disassemble

20. The opposite position of the reset lever should be designed with a cushion insert. (Easy to process and resistant to collisions)

21. The design of the ejector hole of the mold below 300mm is ¢45mm; the design of the mold larger than 300mm is ¢60mm (large mold depends on the situation).

There should be more than 5 ejector holes for molds above 22.400mm.

23. The gas cap is D-shaped gas cap on the inclined plane.

24. The 4 corners of the oblique top and the square small straight top block should form an R angle (to reduce friction).

25. The stripper can be designed as a top ring type as far as possible.